The 2nd Symposium on Taiwan Additive Manufacturing

Time:Saturday, December 20, 2025

Location:Location: Room 115, Henglong Taili Hall, 110-1, 110-2 Comprehensive Science Building, National Taipei University of Technology

In recent years, Additive Manufacturing (AM) in Taiwan has steadily advanced toward applications requiring high precision, customization, and high added value, including the aerospace, medical, and green energy sectors. Despite the growing collaboration between industry and academia, there has long been a lack of an academic conference dedicated specifically to Additive Manufacturing.

Following its establishment, the Additive Manufacturing Society of Taiwan (AMST) responded to the expectations of both industry and academic communities by successfully hosting the First Conference on Additive Manufacturing in 2024, which received an enthusiastic response. This year, we will continue this effort by organizing the Second Conference on Additive Manufacturing. Through this event, we aim to establish a cross-disciplinary platform for communication, strengthen industry–academia collaboration, and share the latest research findings and practical case studies, collectively promoting the long-term development and international visibility of Taiwan’s Additive Manufacturing technologies.

Submission schedule

Regardless of application, all applications must be related to laminated manufacturing.

Download Submission Template

Submission Email

Registration fee schedule download

Provisional Agenda

Keynote speaker:

Prof. Yuan-Hui Chueh

Introduction:

Institute of Applied Mechanics, National Taiwan University

Title:

Multi-Material LPBF for Next-Generation Advanced Manufacturing: Challenges and In-Situ Monitoring Strategies

Abstract:

Multi-material Laser Powder Bed Fusion (LPBF) enables the integration of metals with distinct thermal, mechanical, and functional characteristics, allowing the fabrication of components with unprecedented design flexibility and performance. Despite its promise, combining dissimilar materials introduces significant challenges, including cross-contamination, melt-pool instability, heterogeneous energy absorption, and interfacial defects. This keynote first discusses the fundamental processing difficulties inherent to multi-material LPBF and their implications for part quality and interface reliability. It then highlights recent advances in in-situ monitoring—such as optical spectroscopy, hyperspectral imaging, thermal and melt-pool sensing, and acoustic emission measurements—that capture material-dependent signatures during fabrication. These monitoring approaches provide critical insights into process stability, contamination behavior, and interface formation, offering a pathway toward robust and high-quality multi-material additive manufacturing.

Keynote speaker:

Prof. Dian-Ru Li

Introduction:

Department of Mechanical Engineering, National Taiwan University

Title:

Development of a Next-Generation Intelligent Additive Manufacturing Process Monitoring and Real-Time Error Correction System: An Extrusion-Based Case Study

Abstract:

This talk introduces our team’s development of a next-generation intelligent monitoring and real-time error correction system for extrusion-based additive manufacturing. Unlike conventional approaches that rely on external sensors or offline inspection, our framework uses only camera images and deep neural networks to predict key process parameters, detect abnormalities, and automatically correct errors during printing. This sensor-free, vision-driven strategy significantly simplifies system integration and enables highly responsive, automated control. By incorporating a dynamic monitoring interval and an automatic corrective pause mechanism, the system can intervene within 10–30 seconds of error onset, reducing material waste and stabilizing the build process. Across extensive testing, including single-layer and double-layer prints as well as intentionally induced defects, the system consistently reduced error lengths to below 5 mm and successfully corrected every trial. Additional case studies featuring complex geometries further demonstrated strong generalizability, maintaining extrusion quality and dimensional accuracy comparable to error-free prints. Mechanical testing confirmed that parts preserved their tensile properties even after real-time correction, indicating that the intervention does not compromise structural integrity. Notably, the system also adapted well to irregular or previously unseen defect types, successfully correcting conditions not included in the training dataset. Overall, this vision-based, sensor-free framework represents a scalable and effective solution for in-situ monitoring and real-time correction in additive manufacturing. It offers a promising pathway toward robust, autonomous, and precision-driven smart manufacturing systems.

Keynote speaker:

Prof. Chia-Hung Hung

Introduction:

Department of Mechanical Engineering, National Cheng Kung University

Title:

Fabrication of High-Strength Alloy Parts by Laser-Foil-Printing Additive Manufacturing

Abstract:

Laser Foil Printing (LFP) is a promising metal additive manufacturing technique that utilizes metallic foils as feedstock and aims to fabricate high-strength alloy components with enhanced performance. Compared with laser powder bed fusion (LPBF), LFP offers higher thermal conductivity, extremely low oxidation, and rapid cooling characteristics, effectively suppressing cracking and porosity during processing. LFP has been successfully applied to materials such as 304L/316L stainless steels, AA6061 aluminium alloy, AZ31B magnesium alloy, Ti-6Al-4V, and Zr-based bulk metallic glasses, all of which can be fabricated into high-density 3D components with refined grain structures or fully amorphous phases. Thus, LFP presents excellent mechanical performance and broad material compatibility, making it a key technology for producing high-strength metal components and enabling multi-material additive manufacturing.

Keynote speaker:

Prof. YEN-TING LI

Introduction:

Mechanical and Electro-Mechanical Engineering, Tamkang University

Title:

Next-Generation Binder Jetting for Intelligent Casting: From Physics-

Based Models and Grayscale Compensation to AI-Driven Sustainable Manufacturing

Abstract:

Binder Jetting (BJ) is propelling the foundry industry toward a new era of patternless mass production. However, the technology faces significant challenges, primarily the trade-off between strength and precision due to invisible binder infiltration, along with environmental concerns regarding waste materials . This keynote first discusses a predictive mechanism based on a Simplified Geometric Model to fundamentally understand droplet diffusion and infiltration behaviors within the powder bed . It then introduces a novel "Binder Compensation Mechanism" implemented via a patented Grayscale Printing System. By dynamically adjusting binder saturation based on geometric features, this strategy effectively eliminates gravity-induced errors and optimizes structural integrity . Regarding sustainability, the application of Recycled Sand is highlighted, revealing how sintered, rounded grains can achieve mechanical properties superior to new sand while substantially reducing material waste . Finally, the presentation explores the future integration of these physical models with computer vision and AI-driven adaptive control, establishing a foundation for high-precision, low-carbon smart manufacturing.

Invited speaker:

Introduction:

Freentity

Title:

Freentity: Advancing Vat Photopolymerization 3D Printing Toward Smart Manufacturing

Abstract:

As global manufacturing moves toward extreme customization and rapid iteration, a fundamental question emerges: is 3D printing merely a prototyping tool, or can it truly shoulder the demands of mass production? Freentity seeks to challenge this long-overlooked issue. Built on high-precision DLP 3Dprinting systems, and reinforced with our self-developed optical field compensation algorithms and high-performance engineering materials, we can consistently maintain micro-feature dimensional accuracy within ±20–30 μm—granting photopolymerized components “engineering-grade” reliability for the first time.

More importantly, Freentity integrates equipment, materials, and manufacturing services into a cohesive smart-manufacturing solution. From topology-optimized design to automated, small-batch, multi-variety production lines, we enable complex components to achieve a closed-loop process—from design to mass production—at speeds far exceeding CNC machining and injection molding. This not only redefines the role of VP printing but also forces us to reconsider whether traditional manufacturing is still sufficient in an era where global supply chains demand unprecedented agility and speed.

Freentity’s innovation extends far beyond improving the printing process itself; it reshapes the very mindset of manufacturing, empowering enterprises to transition

Invited speaker:

Prof. Chien-Hua Chen

Introduction:

Department of Chemical Engineering and Material Engineering, National Ilan University

Title:

Scalable Catalytic 3D Printing Process Development—Enabling Smart Transformation in Chemical Reactor Bed Design and Manufacturing

Abstract:

This talk will share the technological achievement—"Scalable Catalyst 3D Printing Full Process Development"—which the team recently received the 2025 NSTC Future Tech Award for. The technology aims to realize the smart transformation of chemical reactor bed design and manufacturing, promoting global net-zero sustainability goals. Addressing the pain point of insufficient process flexibility in current catalytic reactor systems, the research team, combining years of experience in filtration/separation and digital manufacturing, proposes a 3D printing process with high industrial realizability. The core technology involves developing a photocurable catalyst slurry with high reactivity and printability, coupled with Triply Periodic Minimal Surface (TPMS) structure modeling, and manufacturing via a DLP 3D printing equipment developed through industry-academia collaboration. Following printing, the product undergoes post-treatments such as debinding, sintering, carbonization, or metal implantation, resulting in a catalytic reactor with high specific surface area and excellent reaction characteristics. The technology has been successfully applied to the digital manufacturing and in situ synthesis of various materials, including photocatalysts ZnO, zeolites, carbon materials (Tannins), metals 316L, and Metal-Organic Frameworks (MOFs), demonstrating high material and application flexibility. Applications include hydrogen production via water photolysis, degradation of organic pollutants, and CO2 capture. The talk content will cover all aspects, including high catalyst-content formulation design, structural modeling, equipment development, process optimization, AI integration, and application validation.

Invited speaker:

Prof. Hong-Chuong Tran

Introduction:

Department of Mechanical Engineering, National Taipei University of Technology

Title:

Recent Progress on Modeling for Laser Additive Manufacturing and Laser Processing Technology

Abstract:

Recent progress in modeling for Laser Additive Manufacturing and Laser Processing has greatly improved our ability to understand and control laser–material interactions. In our recent work, we developed a multiscale computational framework that predicts hot-cracking behavior in Al6061 by coupling CFD and phase-field modeling, enabling accurate identification of cracking-prone processing windows. We also established a multi-physics simulation model for predicting surface roughness in L-PBF parts, capturing the effects of melt pool dynamics, laser absorption, and thermal gradients on final surface quality. Another study combined numerical and experimental approaches to clarify how processing conditions affect melt pool stability in CuCr1Zr during L-PBF, providing insight into the formation of keyhole and conduction modes. Together, these works highlight how computational modeling can effectively uncover the underlying physics governing melt pool evolution and defect formation. Such models reduce reliance on costly experimental trial-and-error and accelerate parameter optimization.

Invited speaker:

Prof. Chinmai Bhat

Introduction:

Department of Mechanical Engineering, National Taipei University of Technology

Title:

Design and Additive Manufacturing of Technical Textiles Based on Overlapping Tessellation Strategies

Abstract:

This study introduces a novel design and additive manufacturing of technical textiles to achieve tunable mechanical properties through the tessellations of a singular material. The design of these chainmail fabrics was inspired by overlapping tessellation strategies found in biological structures. Two types of chainmail fabrics —BCC and FCC were designed to exhibit high flexibility and stretchability with two-dimensional degrees of freedom. The fabrics were designed to bend along two orthogonal axes and drape around curved surfaces. Furthermore, the relative placement of the unit cells was adjusted to selectively arrest the degrees of freedom, resulting in chainmail fabrics with tunable flexibilities and mechanical properties. Four fabrics for each design Fabric-A, Fabric-B, Fabric-C, and Fabric-D were developed with varying degrees of freedom. All the designed chainmail fabrics were additively manufactured using HP-MJF powder bed fusion technology with a polyamide-12 material. The mechanical properties of the fabricated samples were evaluated through experimental tension tests and numerical simulations. The fabricated BCC and FCC chainmail fabrics exhibited a stress-free zone, followed by an elastoplastic zone, with different mechanical properties observed at different orientations. The FCC fabrics outperformed the BCC fabrics with 45° orientation, exhibiting excellent load-bearing properties, and the 0° orientation showed superior energy absorption capacity. The numerical simulations accurately predicted the mechanical properties and failure locations. Fabric-A was highly flexible but had compromised load-bearing and energy-absorption abilities, whereas Fabric-D acted as a rigid lattice structure with exceptional load-bearing and energy-absorbing properties. FCC fabrics are easier to manufacture using various polymer additive processes owing to their supportless nature. Tunable technical fabrics such as these have potential applications in lightweight and adaptive spinal posture-correcting braces as well as in protective equipment.

Promotional posters

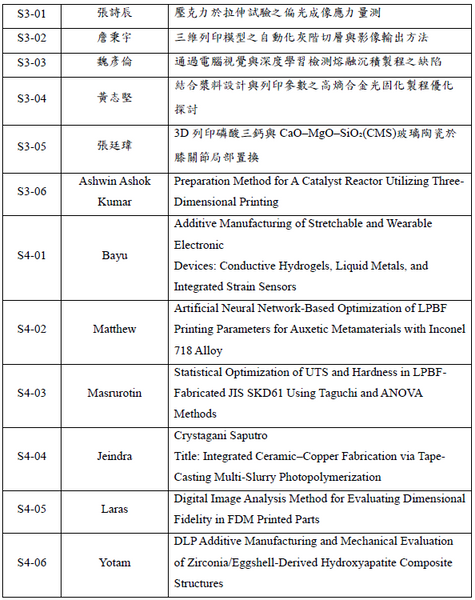

Provisional Agenda